# Technical Data

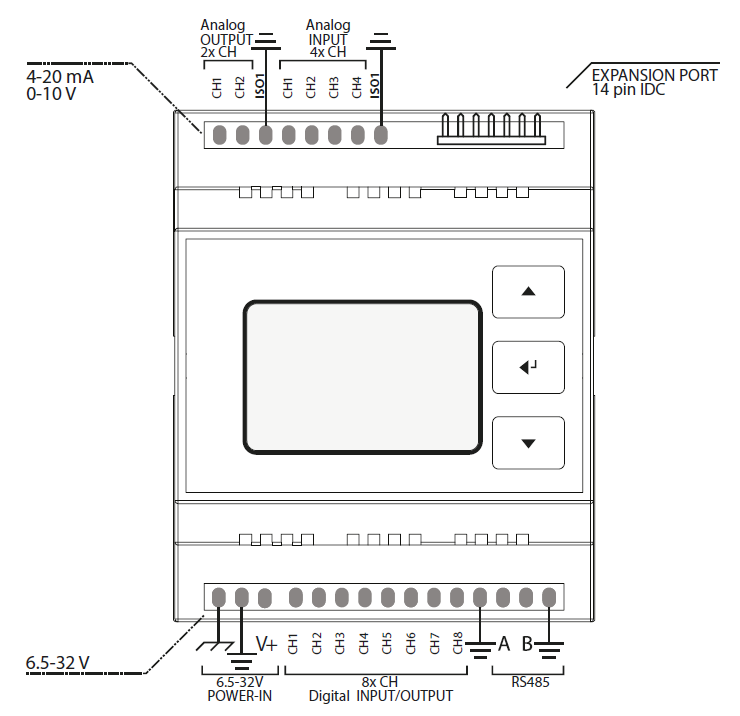

- [](https://help.raindancer.com/uploads/images/gallery/2024-03/9U0image.png)ATSAMD21G18 Microcontroller

- 128x64 px LCD Screen with Backlight

- Membrane 3 Button Panel

- Ethernet Module (mandatory)

M2M 3G/LTE Router optionally available

- Standard Input Voltage: 12V / 24V DC

permissible range: 8–28V DC

12V, 24V PSU optionally available

- DIN-Rail mountable

- 4 Analog Input Channels

- 2 Analog Output Channels

- Levels: 4–20mA / 0–10V

- Fully isolated from MCU and Digital Side (1kV isolation)

- 8 Digital I/O Channels

- Digital Input Voltage Range: 0–28V

input channels internally driven LOW

- Digital Output Vortage Range: 8–28V (tied to VIN)

- Digital I/O Levels: LOW ≤ 3V, HIGH ≥ 11V

I/O Logic is active high

- Max. Output Current per Pin: 2.6A

(short circuit, over-current, over-temp. protected)

- Max. Total Output Current: 6.5A (omni block fused)

- Fully isolated from MCU and Analog Side (1kV isolation)

- Isolated Half Duplex RS-485 Transceiver

#### Important Notes

To properly operate the Raindancer Beacon, it has to be connected to an adequate power supply via the POWER-IN field (12/24V DC is recommended). The USB port on the front casing is not suitable.

When a single power supply is used to power both, Raindancer Beacon and peripherals, the GND lines should be tied together.

Power down all systems (Raindancer Beacon, sensors/actuators) before connecting to the Raindancer Beacon via USB, internal components may irreparably take damage otherwise!

#### Analog Field Section

- Analog Pins can be individually configured, according to the requirements of the devices to be connected: 0-10V or 4-20mA. By default, all Analog Pins are preconfigured to 4-20mA. An alternate configurations can be set using the web-portal.

Pin Assignment and Value Ranges when Used as Pump Control Unit:

- The value ranges can be individually adjusted using the web-portal.

| A OUT | Assignment | Default Range |

| CH 1 | Target / Min. Pressure | 0 – 16 bar |

| CH 2 | Manually Set Pressure | 0 – 16 bar |

| A IN | Assignment | Default Range |

| CH 1 | Current Pressure | 0 – 16 bar |

| CH 2 | Current Power | 0 – 100 kW |

| CH 3 | Current Flow | 0 – 100 m³/h |

| CH 4 | Current Speed | 0 – 3.600 rpm |

#### Digital Field Section

- Output can be configured as a permanent or pulsed signal (125ms – 256s).

Signal configuration can be adjusted using the web-portal.

- Pulse counter (using level raise/fall, max. ca. 60Hz), e.g. for water meters on Digital Channel 8.

- Please note that floating/pulsing input voltages may be transmitted as highly fluctuating input signals, triggering associated actions (e.g. error notification).

Default Pin Assignment and Value Ranges When Used as Pump Control Unit:

| D CH | Assignment | Signal | Interpret. |

| **1 (OUT)** | Control ON | Pulse, 125ms | ON |

| **2 (OUT)** | Control OFF | Pulse, 125ms | OFF |

| **3 (IN)** | Confirmation | Permanent | ON/ OFF |

| **4 (IN)** | Error Code 1 | Permanent | ON/ OFF |

| **5 (IN)** | Error Code 2 | Permanent | ON/ OFF |

| **6 (IN)** | Error Code 3 | Permanent | ON/ OFF |

| **7 (OUT)** | Reset Error | Pulse, 2s |

|

| **8 (IN)** | Counter | Pulse |

|

#### Error Codes

- By combining the three main Error Codes using Digital Channels 4 – 6, four additional states, up to a total of 7, can be transmitted.

- • The textual interpretations of the Error Codes can be customized individually using the web-portal.

Default Error Codes Used by Pump Control/Monitoring:

| Code 1

(CH 4) | Code 2

(CH 5) | Code 3

(CH 6) | Interpretation |

| 0 | 0 | 0 | no malfunction |

| **1** | 0 | 0 | Malfunction - Pressure, generic. |

| 0 | **1** | 0 | Malfunction - Motor Temperature |

| 0 | 0 | **1** | Malfunction - Frequency Inverter / Pump |

| **1** | **1** | 0 | Malfunction - Low Pressure |

| **1** | 0 | **1** | Malfunction - Excess Pressure |

| 0 | **1** | **1** | Restart after Interruption of Power Supply |

| **1** | **1** | **1** | Remote Control Disabled |